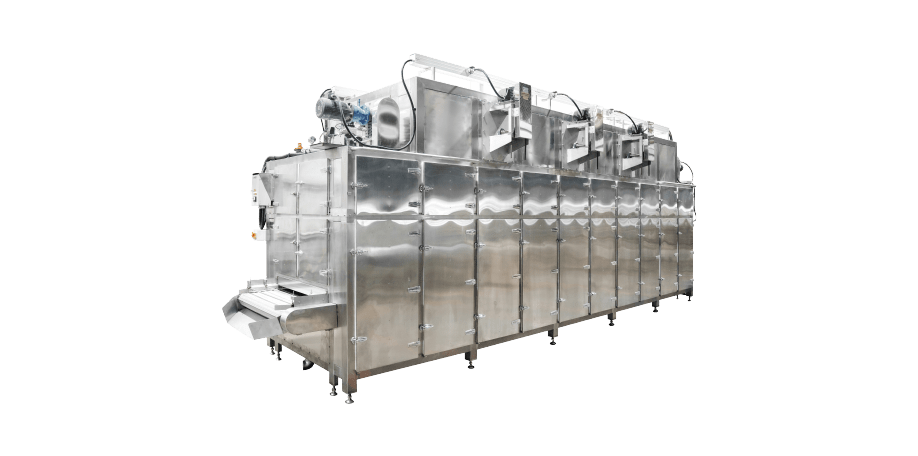

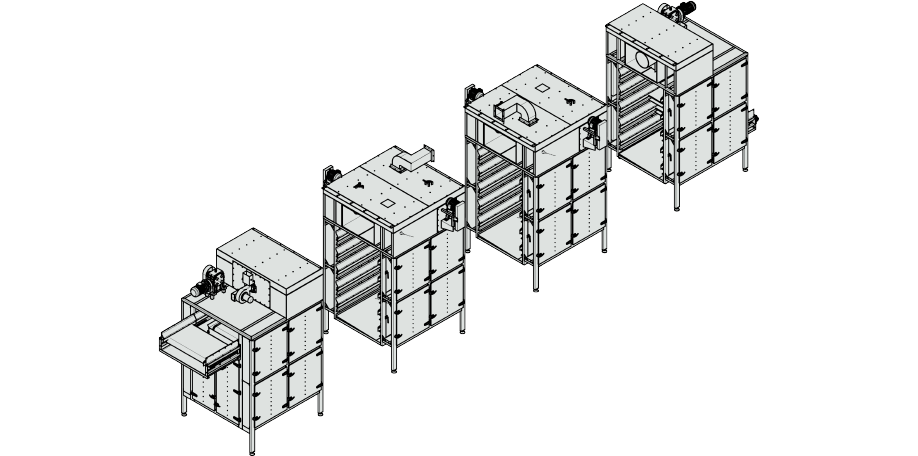

We are a professional plastic products drying equipment manufacturer, dedicated to providing you with the most efficient and high-quality drying equipment. Combining years of experience and professional technologies, we provide you with tailor-made drying solutions. Our equipment features quick drying and low energy consumption. And the space-optimized design makes our equipment occupy less space, suitable for various factory environments, and effectively achieves space saving.

We have always had dedicated personnel to provide customers with feasibility testing services and data record analysis. We welcome you to bring raw materials to TSHS factory to experience the drying effect of the product yourself.

There are many types of plastic raw materials; each of them has its own specific properties, application and processing method. The following materials are some common plastic raw materials: polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), polystyrene (PS), polyoxymethylene (POM), polyetheretherketone (PEEK), nylon (PA), and polyurethane (PU); the above ones are only part of the plastic raw materials. In fact, there are many other plastic materials and synthetic resins, each of which has unique properties and applications.

We are eager to work with the industry to develop and explore more possibilities for plastic products dryer equipment. If you have any needs about plastic products drying machinery or want to know more about our plastic products drying technology, please feel free to contact us via email at [email protected].

Temperature setting: Drying temperature that is too high or too low may affect the properties of the plastic.

Drying time: Various plastic materials have different drying time requirements.

Dry environment: Keep the equipment clean to avoid plastic contamination.

Injection molded products: Toys, tableware, vehicle/aerospace parts, medical equipment, etc.

Extruded products: Water pipes, cable sheaths, and window frames, etc.

Blow molded products: Beverage bottles, detergent bottles, and containers, etc.

Rotation molded products: Large water storage tanks, and traffic roadblocks, etc.